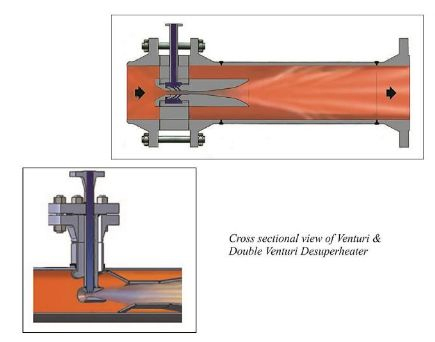

Venturi Steam Desuperheater

Jet Flow venturi desuperheaters consist of a Laval nozzle which utilises a part of the incoming steam flow to create a reduced pressure zone into which spray water is drawn and atomised by steam energy, and then exits in a

short expanding throat which allows pressure recovery.

The desuperheating performance remains constant at all loads from 100% or less, because of the atomising steam effect of the steam jet. The design is unique

such that the spray water can be supplied at the same pressure as that of the steam pressure. High turndowns are possible depending upon

installations.

Specification

Material |

| A182 GR F11 / F22 / F91 |

| A182 GR F11 / F22 / F91 |

| A105 |

| DIN 1.4122 PLASMA NITRIDED / INCONNEL 718 |

| DIN 1.4122 PLASMA NITRIDED / INCONNEL 718 |

| DIN 1.4122 PLASMA NITRIDED / A 182GR F11 / F22 / F91 ST |

| A 182 GR F11 / F22 / F91 |

| DIN 1.4122 PLASMA NITRIDED |

| DIN 1.4122 PLASMA NITRIDED / INCONNEL 718 |

| X120 Cr 29 |

| GRAFOIL |

| A182 GR F11 / F22 / F91 |

| A 182 GR F11 / F22 / F91 |